Impressive Hydraulic System: Hydraulic power is efficiently transmitted upwards, with cylinders mounted on both finishes of your press brake’s higher beam (ram). This direct-drive system makes certain responsive and exact sliding movement.

In this article, we’ve collected some basic details and crucial criteria to assist you reach the desired benefits.

In present day instances, the phrase “press brake” is made use of to explain a hydraulic bending machine that is certainly exclusively made for sheet metal bending.

FRONT SHEET SUPPORTING ARMS are optional however a must have equipment designed to deliver crucial assist for sheet metal in the press braking system.

All metallic structures are crystalline lattices internally, which happen to be repetitive preparations of atoms. As a result, grains are the person crystalline locations within the metal.

This metal-forming method is suitable for making curvature shapes from flat sheets. In the meantime, it's a lot of purposes in tube shaping. You receive far more control above the method to take care of an correct and precise radius.

Other engines like google associate your ad-simply click behavior having a profile on you, that may be applied later on to focus on ads to you personally on that search engine or about the Internet.

Through the higher beam’s speedy descent, if these sensors detect an item thicker than the material currently being bent (including an operator’s arm), they promptly communicate with the press brake’s Handle system to initiate an unexpected emergency halt.

Being aware of ways to bend sheet metal comes along with an being familiar with that components including the thickness of the fabric, measurement on the bend, bend radius, and intended function determine the methods.

These options may be attained with machining or punching with a press Get started brake. There are numerous guidelines regarding their placements in styles;

Analyze product features and technical requirements for significant brand names

At SweBend, we manufacture machines custom-made to the distinct desires, whether you are bending massive beams for bridge constructions or precision bending sheet metal to create spaceships, we contain the solution.

These cookies Collect data to help you us have an understanding of web-site utilization, evaluate advertising and marketing performance, and personalize your working experience.

The metal bending procedure starts off With all the creation of an in depth design of the final section. The CNC bending calls for 3D data files and you may draft the look in software package like AutoCAD and Solidworks.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Devin Ratray Then & Now!

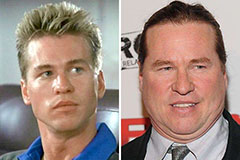

Devin Ratray Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!